Nylon flexible drag chain CNC machine tool cable tray tray drag chain

As one of the Drag Chain manufacturers, suppliers, and exporters of mechanical products, We offer Drag Chain and many other products.

Please get in touch with us for details.

mailto:Mail:[email protected]

Nylon flexible drag chain CNC machine tool cable tray tray drag chain

Introduction

The Nylon flexible drag chain CNC machine tool cable tray tray drag chain is a versatile and essential component for various industries. It is designed to protect cables and wires, ensuring their safety and longevity. With its unique features and advantages, this drag chain offers exceptional protection, improved wear resistance, reduced maintenance needs, enhanced safety, strong adaptability, and cost-effectiveness.

Unique Features and Advantages

- Protection: The drag chain provides comprehensive protection for cables and wires, shielding them from external elements and potential damage.

- Improved Wear Resistance: Its high-quality material and design contribute to increased durability, making it resistant to wear and tear.

- Reduced Maintenance Needs: With its reliable performance, the drag chain minimizes the frequency of maintenance requirements, saving time and resources.

- Enhanced Safety: By securely containing cables and wires, it prevents hazards such as tangling or accidental tripping.

- Strong Adaptability: The drag chain is highly adaptable and can be easily customized to fit various applications and environments.

- Cost Reduction: By protecting cables and wires from damage, it reduces the risk of costly repairs or replacements.

Working Principle

The drag chain operates on a simple yet effective principle. It utilizes a series of interconnected links that allow for smooth and controlled movement of cables and wires. This ensures minimal friction and prevents any entanglement or damage during operation.

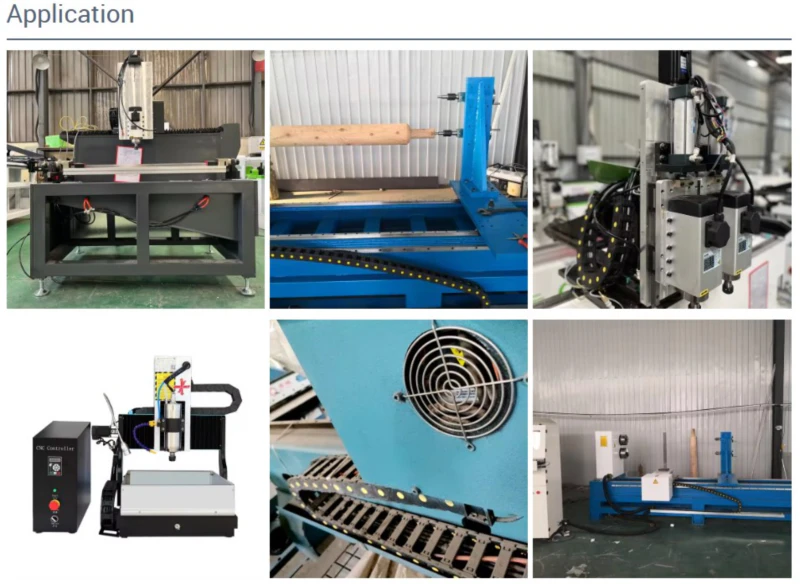

Applications

The Nylon flexible drag chain CNC machine tool cable tray tray drag chain finds extensive usage in various industries, including but not limited to:

- Machinery and automation

- CNC machine tools

- Robotics

- Manufacturing and production lines

- Material handling systems

What is Drag Chain?

Drag Chain is a mechanical device used to protect and manage cables and hoses. It consists of a series of interlocking links that form a flexible channel for the smooth movement of cables. The design typically includes an openable or separable structure for easy installation and maintenance.

Basic Structure and Design

The drag chain is composed of individual links, usually made of durable materials such as nylon or plastic. These links are connected by pins or joints, allowing for flexibility and movement. The chain's design ensures the cables are securely contained and protected during operation.

Wide-Ranging Applications

Drag Chain is widely used in numerous industries, including but not limited to:

- Machine tools and CNC machinery

- Robotic systems

- Material handling equipment

- Automated production lines

- Packaging and printing machinery

Main Functions and Cable/Tube Protection

The primary function of Drag Chain is to protect cables and pipes from external factors that could cause damage or interference. It offers the following benefits:

- Prevents wear and abrasion: The drag chain shields cables and pipes from friction that could lead to premature wear and damage.

- Avoids tangling and entanglement: It keeps cables and pipes organized and prevents them from getting tangled, ensuring smooth operation.

- Reduces maintenance: By providing a secure and protected pathway for cables and pipes, the drag chain minimizes the need for frequent maintenance and repairs.

- Enhances safety: It eliminates tripping hazards and protects personnel from accidental contact with cables or pipes.

- Resists chemicals and contaminants: The drag chain's materials and design make it resistant to various chemicals, oils, and other contaminants found in industrial environments.

Materials Used for Drag Chain Manufacturing

Drag chains are typically made from a variety of materials, including:

- Nylon: Offers excellent durability, flexibility, and resistance to wear.

- Plastic: Provides a cost-effective solution with good resistance to impact and corrosion.

- Steel: Ensures maximum strength and durability for heavy-duty applications.

- Aluminum: Combines lightweight construction with high strength and corrosion resistance.

Manufacturing Process and Techniques

The production of drag chains involves several steps and processes:

- Material selection and preparation

- Mold design and fabrication

- Injection molding or extrusion

- Link assembly and connection

- Quality control and testing

Impact of Material and Manufacturing Techniques on Drag Chain Performance

The choice of materials and manufacturing techniques can significantly affect the performance of drag chains:

- Material selection: Different materials offer varying levels of durability, flexibility, and resistance to wear, chemicals, and temperature.

- Manufacturing techniques: The manufacturing process determines the precision, strength, and overall quality of the drag chain.

Choosing the Right Drag Chain for Specific Applications

When selecting a drag chain, it is crucial to consider specific application requirements:

- Environmental conditions (temperature, humidity, chemicals)

- Movement range and speed

- Load capacity

- Size and space limitations

- Cable and pipe diameter

Installation Steps and Precautions for Drag Chain

Proper installation of the drag chain is essential for optimal performance and longevity. Follow these steps and precautions:

- Carefully measure and plan the installation route

- Ensure sufficient space and clearance for movement

- Securely attach the drag chain to the mounting surface

- Avoid overloading the drag chain beyond its specified capacity

- Regularly inspect and clean the drag chain for any debris or damage

Company Information:

Our company holds a leading position in the Chinese chain market. We specialize in the production and supply of various drag chains, including nylon flexible drag chains, plastic drag chains, and tabletop chains. With a state-of-the-art manufacturing facility equipped with 300 sets of automatic CNC production equipment, we ensure the highest quality standards and efficient production processes.

We take pride in our commitment to delivering superior products, competitive prices, and excellent customer service. We welcome customization requests based on customer specifications and samples. Feel free to reach out to us for any inquiries or orders.

Thank you for considering our company and products. We look forward to serving you!