Drag Chains in Automated Car Wash Systems

Introduction

In the world of automated car wash systems, drag chains play a crucial role in ensuring the smooth and efficient operation of the equipment. These chains, known for their durability and flexibility, are designed to withstand the harsh conditions of a car wash environment. In this article, we will explore the various aspects of drag chains and their significance in automated car wash systems.

1. Understanding Drag Chains

Drag chains, also referred to as cable carriers or energy chains, are mechanical components used to guide and protect cables and hoses in automated systems. They are typically made up of interconnected links that form a flexible chain-like structure. These chains are designed to move along a predefined path, allowing the cables and hoses to move freely while preventing tangling or damage.

2. Importance of Drag Chains in Car Wash Systems

2.1 Protection from External Elements

Automated car wash systems are exposed to various external elements such as water, cleaning chemicals, and debris. Drag chains act as a protective shield, preventing these elements from reaching and damaging the cables and hoses within the system.

2.2 Ensuring Cable and Hose Management

The proper management of cables and hoses is vital for the efficient operation of an automated car wash system. Drag chains provide a structured pathway for these components, ensuring organized and tangle-free movement. This reduces the risk of downtime and maintenance issues due to cable or hose damage.

2.3 Flexibility and Durability

Drag chains are designed to withstand the continuous movement and harsh operating conditions of a car wash system. Their flexible yet robust construction allows them to adapt to different directions and angles, providing a reliable and long-lasting solution.

3. Application of Drag Chains in Automated Car Wash Systems

Drag chains find extensive use in various components of automated car wash systems. Some key applications include:

3.1 Conveyor Systems

Drag chains are commonly used in conveyor systems to guide and protect the cables and hoses that power the movement of the conveyor belts. They ensure smooth and uninterrupted power supply, contributing to the overall efficiency of the system.

3.2 Brush and Spray Systems

In brush and spray systems, drag chains play a crucial role in cable and hose management. They allow the cables and hoses to move along with the brushes or spray nozzles, facilitating the proper functioning of these essential components.

3.3 Control Panels

Control panels are the nerve center of any automated car wash system. Drag chains are employed to organize and protect the cables that connect various control elements, ensuring reliable and uninterrupted communication.

4. Our Leading Company and Products

At our company, we are proud to be a leading player in the Chinese chain market. We specialize in the production and supply of various drag chain products that cater to the unique needs of automated car wash systems. Our product range includes:

4.1 Drag Chain

4.2 Flexible Chain

4.3 Plastic Drag Chain

4.4 Bushchains

4.5 Plastic Chains

4.6 Tabletop Chain

4.7 Multiflex Chain

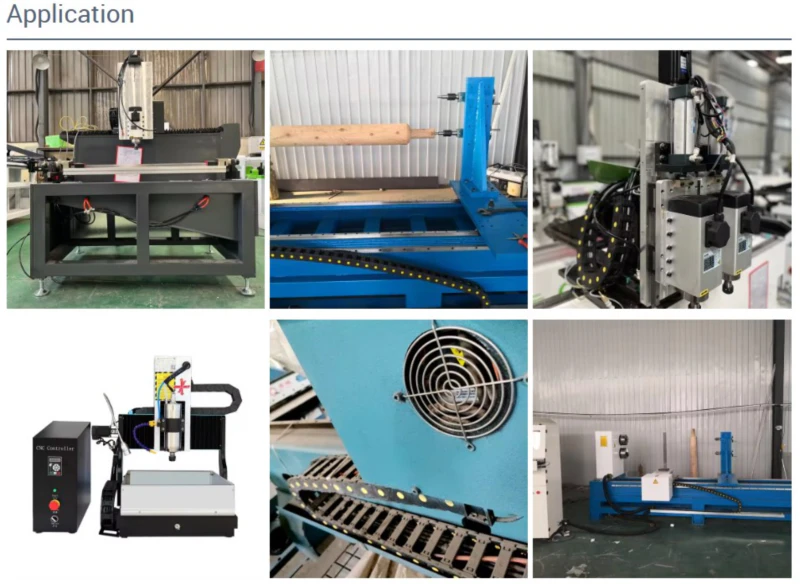

With 300 sets of advanced CNC production equipment and fully automated assembly facilities, we ensure the highest quality standards for our products. Our commitment to providing superior products, competitive prices, and attentive service sets us apart in the industry. We welcome customization requests from our valued customers.

If you are looking for reliable and durable drag chains for your automated car wash system, look no further. Contact us today to experience the difference our high-quality products can make in optimizing the performance of your car wash equipment.

Author: Czh