Drag Chains for Welding Machines

Introduction

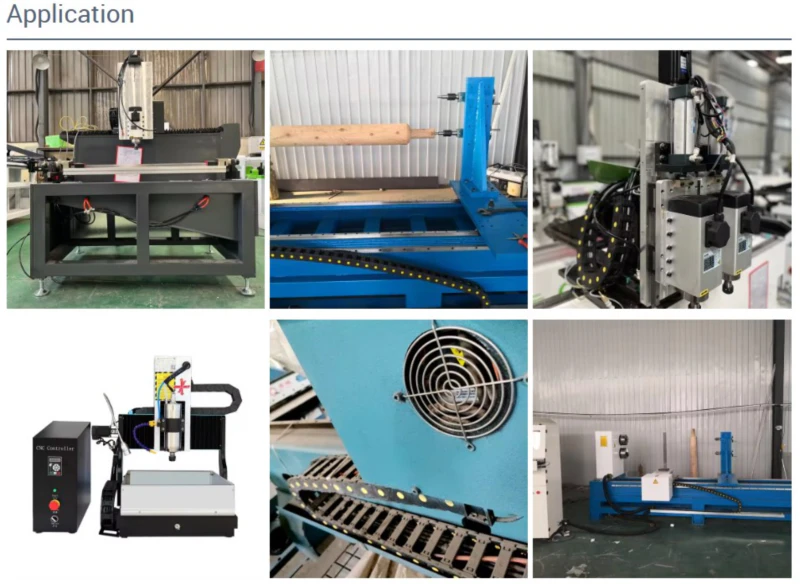

In the welding industry, the importance of drag chains cannot be overstated. These essential components play a crucial role in protecting cables and hoses, ensuring smooth and uninterrupted operation of welding machines. In this article, we will explore the various aspects of drag chains for welding machines, their features, applications, and benefits.

1. Understanding the Function of Drag Chains

Drag chains, also known as cable carriers, are designed to house and protect cables, hoses, and other conductive elements in welding machines. They facilitate the smooth movement of these elements while preventing tangling, damage, and interference. The use of drag chains ensures optimal performance and longevity of welding machines by minimizing downtime and maintenance costs.

2. Types of Drag Chains

There are several types of drag chains available for welding machines, each with its unique features and advantages. These include:

- Metal Drag Chains: These are robust and durable chains made from high-quality metals such as steel or aluminum. They offer excellent protection against external factors and are ideal for heavy-duty welding applications.

- Plastic Drag Chains: Made from high-grade plastic materials, these chains are lightweight, flexible, and resistant to corrosion. They provide reliable cable protection and are suitable for various welding environments.

- Flexible Chains: As the name suggests, flexible chains offer enhanced flexibility, allowing for easy cable movement in different directions. They are highly adaptable and widely used in welding machines with complex cable routing.

- Bushchains: Bushchains are specialized drag chains designed to accommodate larger cables and hoses. They provide ample space for thick and heavy conductive elements, ensuring optimal performance and reliability.

3. Benefits of Using Drag Chains

The use of drag chains in welding machines offers several significant benefits:

- Enhanced Cable Protection: Drag chains effectively shield cables and hoses from external factors such as sparks, welding debris, and mechanical stress, ensuring their longevity and uninterrupted functionality.

- Improved Safety: By organizing cables and hoses within the drag chain, the risk of tripping hazards and accidents is minimized, creating a safer working environment for welders.

- Reduced Downtime: Proper cable management with drag chains minimizes cable damage, tangling, and interference, reducing downtime and maintenance costs associated with cable replacements and repairs.

- Optimized Performance: With cables securely housed in drag chains, welding machines can operate smoothly and efficiently, resulting in improved productivity and higher-quality welds.

4. Our Leading Company in the Chain Market

Our company is a leading provider of drag chains and related products in the Chinese market. We specialize in manufacturing a wide range of high-quality chains, including drag chains, flexible chains, plastic drag chains, bushchains, plastic chains, tabletop chains, multiflex chains, and more. With 300 sets of fully automated CNC production equipment and assembly lines, we ensure superior product quality and efficient manufacturing processes.

5. Experience Our Top-Quality Products and Services

At our company, we take pride in offering top-quality products, competitive prices, and excellent customer service. We provide custom solutions based on customer requirements, welcoming customers to provide their specifications for tailor-made products. Experience our exceptional products and customer-centric approach today.

Author: Czh