Drag Chains for Synthetic Material Manufacturing

Drag chains play a critical role in the synthetic material manufacturing industry. These innovative components are designed to protect and manage cables and hoses, ensuring smooth and efficient operation in various production processes. In this article, we will explore the key features and benefits of drag chains, as well as their versatile applications in synthetic material manufacturing.

1. Understanding Drag Chains

Drag chains, also known as cable carriers or energy chains, are mechanical systems that enclose and guide cables and hoses along a defined path. They consist of a series of interconnected links or segments that provide flexibility and durability. The primary purpose of drag chains is to prevent damage to cables and hoses caused by bending, abrasion, or torsion during dynamic movements.

2. Importance in Synthetic Material Manufacturing

The synthetic material manufacturing industry heavily relies on drag chains to ensure uninterrupted production processes. From extrusion lines to injection molding machines, drag chains provide crucial cable and hose management solutions. They protect sensitive wiring and fluid lines, preventing downtime and minimizing the risk of costly repairs.

3. Key Features and Benefits

Drag chains offer several features and benefits that make them indispensable in synthetic material manufacturing:

3.1 Superior Cable Protection

The robust construction of drag chains shields cables and hoses from harsh manufacturing environments, such as chemical exposure, high temperatures, or heavy vibrations. This protection extends the lifespan of cables, reducing maintenance and replacement costs.

3.2 Flexible Design

Drag chains are available in various sizes and configurations, allowing customization to fit specific applications. Their flexibility enables smooth cable and hose movement, minimizing friction and ensuring optimal performance.

3.3 Easy Installation and Maintenance

With user-friendly designs, drag chains are easy to install and maintain. Quick access to cables and hoses simplifies routine inspections, repairs, and replacements, reducing downtime and optimizing productivity.

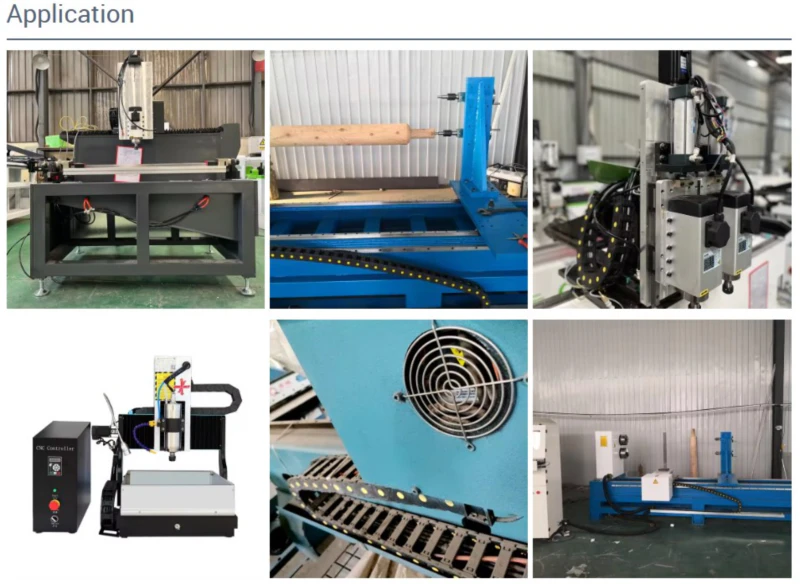

4. Versatile Applications

Drag chains find extensive use in different stages of synthetic material manufacturing processes:

4.1 Extrusion Lines

In extrusion lines, drag chains guide cables and hoses that provide power, control signals, and cooling fluids to extruders, ensuring continuous and reliable operation.

4.2 Injection Molding Machines

Injection molding machines rely on drag chains to manage cables and hoses that facilitate precise control and monitoring of the molding process.

4.3 Material Handling Systems

Drag chains play a crucial role in material handling systems, protecting cables and hoses that control conveyors, robots, and other automated equipment.

5. Company Promotion and Introduction

Author: Czh

At [Company Name], we are a leading provider of drag chains in the Chinese market. Our extensive range of products includes drag chains, flexible chains, plastic drag chains, bushchains, plastic chains, tabletop chains, multiflex chains, and more. We pride ourselves on our state-of-the-art manufacturing facilities, consisting of 300 sets of automated CNC production equipment and assembly machinery.

We are committed to delivering high-quality products, competitive pricing, and exceptional customer service. We welcome custom orders based on specific requirements, and our expert team is dedicated to ensuring customer satisfaction.

Experience the reliability and performance of our drag chains for synthetic material manufacturing. Contact us today to discuss your cable and hose management needs.

Author: Czh