Drag Chains for Satellite Assembly Lines

Introduction

Drag chains play a crucial role in satellite assembly lines. These chains, also known as cable carriers, are designed to protect and route cables and hoses in a safe and organized manner. In this article, we will explore the various aspects of drag chains for satellite assembly lines, including their importance, types, applications, and benefits.

Types of Drag Chains

There are several types of drag chains commonly used in satellite assembly lines:

- Metallic Drag Chains

- Plastic Drag Chains

- Flexible Drag Chains

- Bushchains

- Tabletop Chains

- Multiflex Chains

Metallic Drag Chains

Metallic drag chains, also known as steel drag chains, are known for their high strength and durability. They are suitable for heavy-duty applications and provide excellent protection for cables and hoses in harsh operating conditions.

Plastic Drag Chains

Plastic drag chains, on the other hand, offer lightweight and cost-effective solutions. They are highly flexible and provide ample space for cable routing. Plastic drag chains are commonly used in satellite assembly lines where weight reduction and flexibility are essential.

Flexible Drag Chains

Flexible drag chains are designed to accommodate complex cable and hose layouts. They offer excellent flexibility and can bend in multiple directions without affecting the performance of the cables and hoses. These chains are ideal for satellite assembly lines that require intricate cable routing.

Bushchains

Bushchains, also known as tube chains, are used to guide and protect cables and hoses. They are made up of interconnected plastic tubes that provide a secure and organized pathway for cables. Bushchains are commonly used in satellite assembly lines where precise cable guidance is required.

Tabletop Chains

Tabletop chains are used in satellite assembly lines to transport and accumulate satellite components. They offer a flat surface that ensures smooth and reliable movement of the components. Tabletop chains are highly efficient and can handle heavy loads without compromising performance.

Multiflex Chains

Multiflex chains are designed to provide maximum flexibility and versatility. They can be easily reconfigured and adapted to different cable and hose layouts. Multiflex chains are commonly used in satellite assembly lines where frequent changes in cable routing are required.

Applications of Drag Chains

Drag chains find wide-ranging applications in satellite assembly lines, including:

- Protection of cables and hoses

- Prevention of tangling and damage

- Provision of organized cable routing

- Facilitation of smooth cable movement

- Reduction of maintenance and downtime

Benefits of Drag Chains

The use of drag chains in satellite assembly lines offers numerous benefits, such as:

- Enhanced cable protection

- Improved cable lifespan

- Reduced cable maintenance

- Minimized downtime

- Increased operational efficiency

Company Overview

Author: Czh

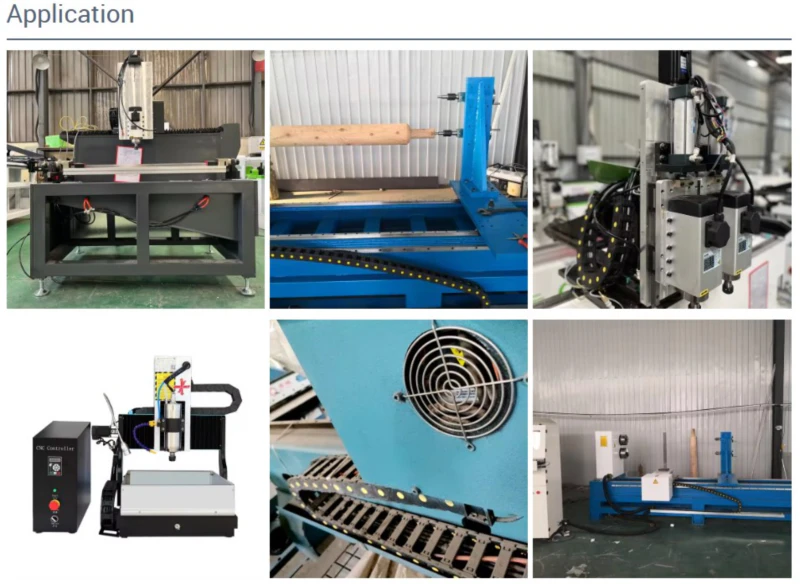

Our company is a leading player in the chain market in China. We specialize in manufacturing and supplying a wide range of high-quality chain products, including drag chains, flexible chains, plastic drag chains, bushchains, plastic chains, tabletop chains, multiflex chains, and more. With 300 sets of advanced CNC production equipment and fully automated assembly facilities, we ensure the highest standards of quality and precision in our products.

In addition to our top-notch products, we pride ourselves on offering competitive prices and excellent customer service. We welcome customers to customize their chain solutions according to their specific requirements. Your satisfaction is our priority.

Thank you for reading our article on drag chains for satellite assembly lines. If you have any further questions or would like to explore our product offerings, please don’t hesitate to contact us.