Drag chains for precision applications

Drag chains are an essential component in precision applications where reliable cable and hose routing is crucial. With their ability to protect and guide cables, drag chains ensure smooth and uninterrupted movement, preventing any damage or tangling that may impede the overall performance of machinery. In this article, we will explore the various aspects of drag chains, their benefits, and their applications in precision settings.

The Importance of Drag Chains

Drag chains play a vital role in precision applications, providing a secure and organized system for cable and hose management. Their robust construction and flexibility allow for easy installation and movement, ensuring optimum performance and longevity of the equipment they are installed in.

Benefits of Drag Chains

Drag chains offer several advantages in precision applications:

- Protection: Drag chains protect cables and hoses from external factors such as abrasion, dust, and moisture, extending their lifespan and preventing costly downtime.

- Guidance: By guiding cables and hoses along a predefined path, drag chains minimize the risk of entanglement or tangling, ensuring smooth and reliable operation.

- Flexibility: The flexibility of drag chains allows for easy movement and routing of cables, accommodating changes in direction and length without compromising their functionality.

- Durability: With their rugged construction and high-quality materials, drag chains can withstand demanding environments and heavy usage, providing long-lasting protection and support.

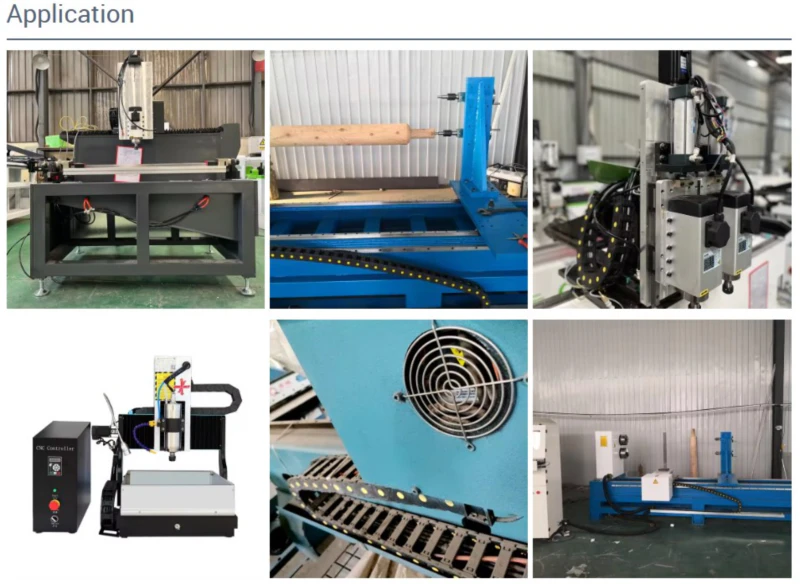

Applications of Drag Chains

Drag chains find extensive use in various precision applications, including but not limited to:

- CNC Machines: Drag chains are crucial in CNC machines, protecting cables and hoses while allowing for precise and rapid movement.

- Robotics: In robotic systems, drag chains ensure the safe and efficient operation of cables and hoses, minimizing the risk of interference or damage.

- Medical Equipment: Drag chains play a vital role in medical equipment, ensuring the smooth routing of cables and hoses in precision instruments.

- Automation Systems: In automated manufacturing processes, drag chains provide reliable cable management, optimizing productivity and minimizing downtime.

Conclusion

In precision applications, drag chains are indispensable for the efficient and secure management of cables and hoses. Their ability to protect, guide, and flexibly route cables ensures optimal performance and longevity of machinery. As a leading company in the Chinese chain market, we specialize in providing top-quality drag chains, flexible chains, plastic drag chains, bushchains, plastic chains, tabletop chains, multiflex chains, and more. With 300 sets of fully automated CNC production equipment and assembly devices, we are committed to delivering high-quality products, competitive prices, and excellent customer service. Customization options are also available, where customers can provide their specific requirements and designs.

If you are in need of reliable and durable drag chains for your precision applications, look no further. Contact us today to discuss your requirements and experience the difference of our superior products and attentive service.

Author: Czh

Thank you for reading our article on drag chains for precision applications. We appreciate your interest and welcome you to explore our wide range of products tailored to meet your specific needs. With our leading position in the Chinese chain market and a commitment to quality, competitive pricing, and attentive service, we are confident in providing the best solutions for your cable and hose management requirements. For custom orders or further inquiries, please do not hesitate to contact us. We look forward to serving you.