Drag Chains for Automated Packing Machines

Introduction

Automated packing machines play a crucial role in modern manufacturing processes. To ensure the smooth and efficient operation of these machines, it is essential to have reliable and durable drag chains in place. In this article, we will explore the importance of drag chains and their various applications in automated packing machines.

Understanding Drag Chains

Drag chains, also known as cable carriers or energy chains, are specially designed to protect and guide electrical cables and hoses in automated machinery. They provide a safe and organized pathway, ensuring the cables remain protected from external factors such as dust, debris, and abrasion. Drag chains are essential components in automated packing machines, as they prevent cable damage and reduce the risk of downtime.

Benefits of Drag Chains

1. Enhanced Cable Protection: Drag chains offer excellent protection to cables and hoses, preventing them from snagging, tangling, or getting damaged during machine operation.

2. Improved Machine Performance: By keeping the cables organized and protected, drag chains contribute to the smooth operation of automated packing machines, minimizing the risk of cable malfunctions and downtime.

3. Increased Machine Lifespan: With drag chains in place, the lifespan of cables and hoses is significantly extended, reducing the need for frequent replacements and maintenance.

4. Flexible and Customizable: Drag chains come in various sizes, designs, and materials, allowing for customization based on specific machine requirements.

Applications of Drag Chains in Automated Packing Machines

1. Conveyor Systems: Drag chains are commonly used in conveyor systems of automated packing machines. They protect and guide cables that power the conveyor belts, ensuring smooth and uninterrupted movement of goods.

2. Packaging Machines: Drag chains are essential in packaging machines, providing a secure pathway for cables that control the machine’s various functions, such as sealing, labeling, and filling.

3. Robotic Arms: Automated packing machines often incorporate robotic arms for precise and efficient handling of products. Drag chains protect and manage the cables that power these robotic arms, ensuring their seamless operation.

Using Drag Chains in Real-Life Scenarios

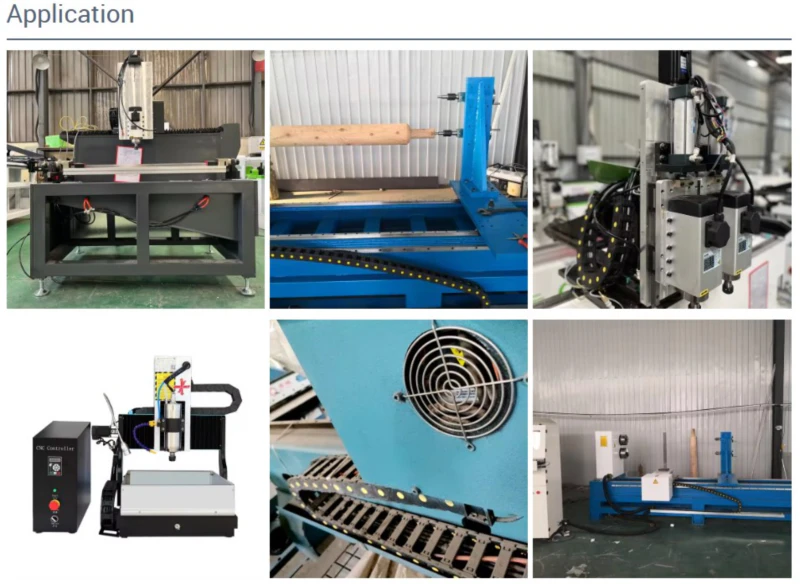

In a typical automated packing setup, drag chains are used to protect and manage cables in conveyor systems, packaging machines, and robotic arms. The image below demonstrates a drag chain in action within an automated packing machine:

Company Introduction

At our company, we are a leading player in the Chinese chain market, specializing in providing high-quality drag chains and other chain-related products. With a wide range of offerings, including drag chains, flexible chains, plastic drag chains, bushchains, plastic chains, tabletop chains, and multiflex chains, we cater to diverse industrial needs.

We boast a state-of-the-art manufacturing facility equipped with 300 sets of various fully automated CNC production equipment and assembly machines. This enables us to deliver products of utmost precision and durability.

Company Product Promotion

Our company takes pride in offering top-of-the-line products at competitive prices, accompanied by exceptional customer service. We guarantee the quality and reliability of our drag chains for automated packing machines, ensuring smooth and efficient operation.

Whether you require standard drag chains or custom solutions, we are here to meet your specific requirements. Our team of experts is dedicated to providing personalized assistance and prompt support throughout the process.

We invite customers to avail themselves of our customization services, where we can design and manufacture drag chains based on your unique needs. Your satisfaction is our priority, and we strive to exceed your expectations.

Factory Image

Author: Czh