Customizable Drag Chains

Introduction

In this article, we will explore the world of customizable drag chains and their various applications in different industries. Drag chains are an essential component in many machinery systems as they provide protection and support for cables and hoses, ensuring smooth and efficient operation. Their ability to be customized makes them highly versatile and adaptable to specific needs. Let’s delve into the details of this innovative technology.

Chapter 1: Understanding Drag Chains

Drag chains, also known as cable carriers or energy chains, are mechanical systems designed to organize and protect cables and hoses in motion. They consist of a series of interconnected links that form a flexible and durable chain. These chains can be easily opened, allowing for convenient cable installation and maintenance. With their robust construction and high load-bearing capacity, drag chains offer reliable cable protection.

Section 1: Structure and Components

Drag chains typically consist of four main components:

- The outer links, which form the protective shell of the chain.

- The inner links, which provide flexibility and allow for smooth movement.

- The separator, which keeps the cables and hoses organized within the chain.

- The mounting brackets, which secure the chain to the machine or equipment.

Section 2: Customization Options

Customizability is one of the key features of drag chains. They can be tailored to specific requirements, ensuring optimal performance and compatibility. Some common customization options include:

- Length: Drag chains can be adjusted to fit different distances and travel lengths.

- Interior Layout: The separator system can be customized to accommodate various types and sizes of cables and hoses.

- Mounting Style: Drag chains can be mounted horizontally, vertically, or even suspended.

- Material: Different materials, such as plastic or metal, can be chosen based on environmental conditions and load requirements.

Chapter 2: Applications of Drag Chains

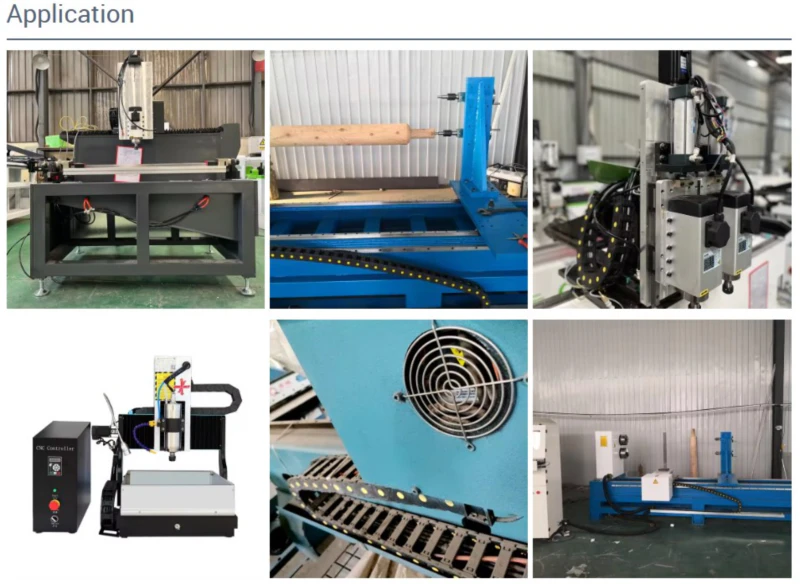

Drag chains find extensive use in a wide range of industries, thanks to their versatility and reliability. Let’s explore some of the common applications:

Section 1: Industrial Automation

In industrial automation, drag chains are used to manage and protect cables and hoses in robotic arms, CNC machines, and other automated systems. They prevent tangling, reduce wear and tear, and ensure consistent cable performance.

Section 2: Machine Tools

Machine tools, such as milling machines, lathes, and drilling machines, often require precise cable management. Drag chains provide the necessary protection and flexibility, allowing for smooth movement of cables and hoses without hindering the machine’s operation.

Section 3: Material Handling

Material handling systems, including conveyor belts and automated warehouses, rely on drag chains to organize and protect cables and hoses. They enable efficient and safe transportation of goods, while minimizing the risk of cable damage.

Section 4: Robotics

In robotics, drag chains are essential for managing the complex cable systems that power robotic arms, grippers, and other robotic components. They ensure reliable cable performance and help prevent cable failure, which can be costly and time-consuming to repair.

Conclusion

Customizable drag chains play a crucial role in ensuring the smooth operation of various machinery systems. Their ability to protect and organize cables and hoses while being customizable makes them a preferred choice in many industries. As a leading company in the Chinese chain market, we offer a wide range of high-quality products, including drag chains, flexible chains, plastic drag chains, and more. With our state-of-the-art production and assembly equipment, we are committed to delivering superior products, competitive prices, and excellent customer service.

About the Author: Czh